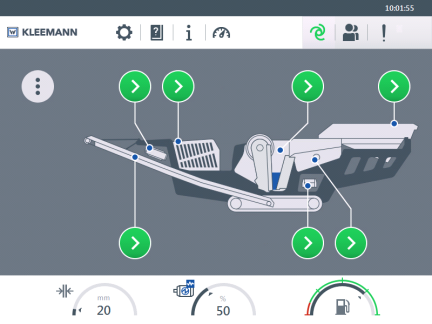

MR 130i PRO Mobile impact crusher

E-DRIVE (Diesel-electric)

41 in x 26 in x 16 in

661

US t/hr

Properties

The MOBIREX MR 130(i) PRO covers a very wide application range in natural stone and recycling. A positive feature of the plant is its all-electric drive concept with the option of an external power supply. The CO2-free operation guarantees low energy consumption per ton of final product.

Show less Highlights

Sustainability meets power play

Feeding unit

Prescreen

CFS

Crusher unit

Control system

Drive

Magnetic separator

Post screening unit

Safety and ergonomics

Environment

Technical specifications

- Max. feed size

- Feed height

- Feed height with extension

- Hopper width

- Hopper width with extension

- Hopper length

- Hopper length with extension

- Hopper volume

- Hopper volume with extension

-

- Max. feed size

- 41 in x 26 in x 16 in

- Feed height

- 14 ft 8 in

- Feed height with extension

- 15 ft 11 in

- Hopper width

- 7 ft 5 in

- Hopper width with extension

- 9 ft 10 in

- Hopper length

- 12 ft 2 in

- Hopper length with extension

- 12 ft 2 in

- Hopper volume

- 6.5 yd³

- Hopper volume with extension

- 11.8 yd³

- Width x length

-

- Width x length

- 44 in x 8 ft 10 in

- Width x length

- Type

-

- Width x length

- 3 ft 12 in x 7 ft 10 in

- Type

- Double-deck heavy-piece screen

- Discharge height

- Width

- Length

- Length (hydraulically foldable) [Imperial]

- Discharge height (hydraulically foldable)

-

- Discharge height

- 11 ft 9 in

- Width

- 26 in

- Length

- 21 ft 8 in

- Length (hydraulically foldable) [Imperial]

- 19 ft x 8 in

- Discharge height (hydraulically foldable)

- 11 ft x 2 in

- Crusher drive type

- Crusher inlet width

- Crusher inlet (W x H)

- Crusher weight (approx.)

- Crusher capacity

- Impact crusher type

- Rotor diameter

- Type of impact toggle adjustment

-

- Crusher drive type

- electric

- Crusher inlet width

- 52 in

- Crusher inlet (W x H)

- 52 in x 36 in

- Crusher weight (approx.)

- 37,500 lbs

- Crusher capacity

- 335 hp

- Impact crusher type

- SHB130-090

- Rotor diameter

- 47 in

- Type of impact toggle adjustment

- stepless, fully hydraulic

- Crushing capacity for demolished concrete up to approx.

- Crushing capacity for mixed rubble up to approx.

- Crushing capacity for demolished asphalt up to approx.

- Crushing capacity for limestone up to approx.

-

- Crushing capacity for demolished concrete up to approx.

- 441 US t/hr

- Crushing capacity for mixed rubble up to approx.

- 496 US t/hr

- Crushing capacity for demolished asphalt up to approx.

- 243 US t/hr

- Crushing capacity for limestone up to approx.

- 441 US t/hr

- Width x length

-

- Width x length

- 57 in x 8 ft 9 in

- Discharge height approx.

- Width

- Crusher discharge conveyor length

-

- Discharge height approx.

- 14 ft 5 in

- Width

- 56 in

- Crusher discharge conveyor length

- 39 ft 8 in

- Drive concept

- Power supply unit output

- Rated speed

- Power pack manufacturer

- Generator

-

- Drive concept

- E-DRIVE (Diesel-electric)

- Power supply unit output

- 641 hp - 2100 hp

- Rated speed

- 2,100 rpm

- Power pack manufacturer

- Scania

- Generator

- 550 kVA

- Transport height approx. (standard value)

- Transport length approx.

- Transport length with secondary screening unit approx.

- Transport width approx.

- Transport width with secondary screening unit max.

- Transport weight of basic plant

- Transport weight max. configuration approx.

- Transport weight of screening unit approx.

-

- Transport height approx. (standard value)

- 12 ft 10 in

- Transport length approx.

- 68 ft 9 in

- Transport length with secondary screening unit approx.

- 76 ft 4 in

- Transport width approx.

- 11 ft 4 in

- Transport width with secondary screening unit max.

- 11 ft 6 in

- Transport weight of basic plant

- 141,150 lbs

- Transport weight max. configuration approx.

- 183,000 lbs

- Transport weight of screening unit approx.

- 28,660 lbs

- Length

- Type

- Oversize grain return conveyor width inches [Imperial]

- Return conveyor length [Imperial]

- Side discharge conveyor (medium grain) width

- Side discharge conveyor (medium grain) length

- Side discharge conveyor (medium grain) discharge height

- Fine grain conveyor discharge height [Imperial]

-

- Length

- 18 ft 1 in

- Type

- Double-deck light-piece screen

- Oversize grain return conveyor width inches [Imperial]

- 26 in

- Return conveyor length [Imperial]

- 36 ft 9 in

- Side discharge conveyor (medium grain) width

- 26 in

- Side discharge conveyor (medium grain) length

- 22 ft x 4 in

- Side discharge conveyor (medium grain) discharge height

- 11 ft x 2 in

- Fine grain conveyor discharge height [Imperial]

- 12 ft x 6 in

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.